But let's begin with a little of the history of the brewery. I've nicked most of this from the Scottish Brewing Archive website. I assume that they've got things right.

The brewery described isn't George Younger's original Meadow Brewery. That was too small. Consequently in 1852 they leased the Candleriggs Brewery of Robert Meiklejohn & Co, which in 1871 they bought. A couple of years later the Meadow Brewery was converted into offices. After rebuilding in 1889 (I wonder if that was before or after Barnards's visit?) it was the largest brewery in Scotland outside Edinburgh. Having seen the capacity of their mash tuns, this comes as no surprise. I reckon they were in the top dozen or so breweries in the UK.

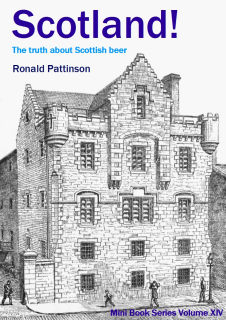

This is what the Meadow Brewery looked like:

They were bought by Northern Breweries of Great Britain Ltd in April 1960 and stopped brewing three years later. There's a car park on the site today. Surprisingly, some of the Meadow Brewery's buildings are still there:

One point of interest: they had big contracts to supply the British armed forces. Seems to have been a specialty of Scottish brewers.

Let's step into the boiling department.

"After having witnessed the operations and apparatus connected with the mashing, we next followed the progress of the wort to the underbacks, placed on the sub-floor beneath the mash-tuns. The worts are pumped therefrom to the coppers by two brass-lined gun-metal double pumps, fixed in close proximity. Passing up the main staircase we reached the copper house, a lofty place shaped like the letter L, 100 feet in length, the leg of the angle measuring 30 feet by 55 feet Here are to be seen four coppers all fitted with copper parachutes; two of them splendid and imposing vessels; the largest we have seen in Scotland. The parachutes of the two larger vessels, which are lifted up and down by a chain and weight, are as large in circumference as some of the usual copper boiling vessels. The capacities of the coppers are as follows: two of 150 barrels, one of 90, and the other of 45 barrels content—the latter is used for porter. They are all brightly polished and kept beautifully clean.

The ventilation of this house is perfect, for not only are the walls latticed here and there, but the roof possesses a box louvre 6 feet high, running nearly the whole length of the building. This department represents a most interesting stage in the art of brewing; boiling being an absolute necessity in the operation. The object sought is the breaking up of the wort and the elimination from it of a large quantity of albumen, which we were informed, owing to the uncertainty of its nature—is better out of the beer. Also the absorption of the flavour and bitterness of the hops, which at this stage are introduced, not only to flavour but also to assist in keeping the beer.

It was an interesting sight to see the "boilers," for so the copper-house men are designated, weigh the required quantity of hops and tip them into the boiling wort ; and it was also very pleasant to inhale the aroma of those costly blossoms. we should here add that each set of men perform but one step in the process, and that all the details are performed by an ingenious application of mechanical power, characterising the whole proceedings by precision, uniformity of results, and accuracy.

From the coppers the wort falls by gravitation to the hop-back, placed on a lower floor. To reach it, we descended to the copper hearth, and from thence down a circular iron staircase, at the Vennel Street side of the structure. The hop-back is a fine cast-iron vessel, with draining plates, which nearly fills a room 55 feet by 35 feet, overlooking the Candleriggs. By its side is a powerful hop-press of an ingenious type suggested by Mr. Younger. It is a roller press, something like a sugar mill, having three rollers, and a this machine is that the hops, having been pressed, pass directly into the carts waiting beneath, and the liquor runs back into the receiver. The press is perfectly continuous in its operation, and easily managed by one man."

"Noted Breweries of Great Britain and Ireland, vol. 2", Alfred Barnard, 1889, pages 438 - 440.

Why did they have a boiler especially for the Porter? I suspect it's no coincidence that it's also the smallest. And by Porter I'm sure Barnard means both Porter and Stout. Straight Porter was pretty much extinct in Scotland by the 1890's. And the quantities of Stout brewed were much smaller than in England. Younger probably only brewed small batches of Stout, hence they used the smallest copper.

The size of the coppers corresponds with the size of the mash tuns. Which shouldn't really be a surprise.

It would be nice if Barnard had explained what the "ingenious application of mechanical power" was in detail. What more is there to do other than to weigh the hops and hoy them in the wort? I can speak with some authority on this matter, having done the hop hoying on several occasions. Once they're in, there's not much to do but sit back, have a beer and wait until it's time to end the boil.

Not sure if I've finished with George Younger yet. I need to check how much more goodness Barnard has about them. Just had a look. Still a few snacks to munch on. There will be a part three. Maybe I could throw in some stuff about other Alloa breweries. You can never have too much contextualisation.

3 comments:

I'm a little unclear about the use of the hop press. Were they pressing the hops to extract any wort that was soaked up, and also easier to dispose of? Or was it to make them available for re-use? Call me crazy, but I think I've heard of some brewers re-using hops.

rabbi, to extract the wort soaked up by the hops.

And yes, they did sometimes re-use hops. Like William Younger in their Stouts.

Not only was Youngers of Alloa the third largest brewer in Scotland, they were family relations to 3 other famous Edinburgh based brewers.

1. Robert Younger & Co.

A younger brother of the head of the family who opened his own brewery in Edinburgh in 1844.

2. John Jeffrey & Co.

Tom and John were maternal uncles of Janet McEwan who married James, head of the Alloa Youngers in 1850.

3. William McEwan & Co.

Janet's brother - her son William Younger became MD of the Fountain Brewery when his uncle William entered politics in 1886.

However, the Alloa branch had no direct business connections to any.

Post a Comment